Waterjet Plastic Cutting Machine

1. product presentation of Waterjet plastic cutting machineWater knife cutting done with fine water flow helps cut plastic of almost any shape.While some plastic sheets are thicker, you can handle them easily using water jets.Your plastic parts will not have any deformed and other adverse effects.Wi......

Send Inquiry

Product Description

1. product presentation of Waterjet plastic cutting machine

Water knife cutting done with fine water flow helps cut plastic of almost any shape.While some plastic sheets are thicker, you can handle them easily using water jets.Your plastic parts will not have any deformed and other adverse effects.Without complex skills, you can make your water knife cutting plastic process successful.Therefore, you can use water cutting as one of the steps in making plastic items for consumers and several other purposes.

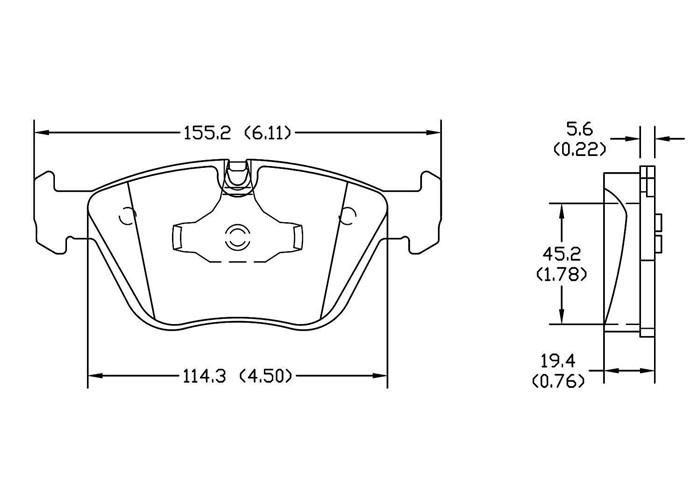

2. Product Parameter of Waterjet plastic cutting machine

Type:gantry cutting table

Size (MM):3900 * 3050

Maximum cut range (MM):X=3000mm Y=2000mm

Z-axis stroke:150mm

Control accuracy:± 0.01mm

Cutting accuracy:± 0.1mm

Repositioning accuracy:± 0.025mm / m

3. Product characteristics and Application of Waterjet plastic cutting machine

Y to double support, two-way ball wire rod, straight guide rail drive, to ensure the operation speed and accuracy of the cutting head.

Unique automatic lubrication system with high quality drag chains and special mobile cables, durable.

Beautiful appearance and convenient transportation.

4. Product Details of Waterjet plastic cutting machine

Pump —— Let's start with the foundation, high pressure pump.Each water knife cutter requires a high pressure pump capable of pumping water at a very high speed.The common water knife cutter uses 480 V, 3 phase, 100 A, 60 Hz pumps.High pressure pump is the core of the water knife cutter.It is responsible for pressurizing the current and continuously through the mixing tube.At this point, the supersonic stream of the water jet emerges from the aperture embedded with gems into the plastic surface.We can find two pumps in Waterjet plastic cutting machines, directly driven and supercharger based.Most plastic water knife cutters use enhancers.

Cutting head The cutting head of the —— water knife is elongated designed objects with high tolerance values.It helps in cutting at right angles.

Control system —— If the high pressure pump is the heart, then the control system is the brain of the water knife carbon fiber cutter.We use the control system to manipulate and perform all the cutting operations.It contains motion control and nozzle positioning that provides the highest accuracy when cutting plastic.

Cutting table The —— cutting table is a solid device that helps cut plastic.It is equipped with a powder coating.Replacement galvanized metal strips are used to extend their service life.

The automatic feed system water knife cutter requires a continuous abrasive flow to continue the cutting process.This is true for the automatic feeding system.It fills the abrasive container where the pressure system is located.The system delivers the abrasive material to the cutter.

5. Product qualification

Perfect cut different hardness and toughness materials according to CE and ISO9001 standards.

6. Deliver,Shipping and Serving Of Waterjet plastic cutting machine

We will provide you with the packaging of the equipment and the shipping to the designated port.The customer service staff at Witt Services will give you the most timely telephone maintenance support and technical problem guidance

6. FAQ

1. How many thick plastic can a water knife cut?

By applying a water knife, you will find it easy to cut 10 inches thick plastic material.You need not take too much effort to complete this task.In addition, the shortest time takes to cut the plastic parts using a water knife.

2. Why are water-jet-cutting plastics better than laser-cutting processes?

Similar to plasma cutting, laser technology consumes a lot of energy.Also, you need to skillfully handle the laser cutting process.There is a risk of inconsistent production speed.That is why you can rely on the water knife cutting process.There is no need to have special skills for this purpose.

3. What is the cutting quality of the water knife?

Water knives are known for providing the best quality plastic sheet cutting.You can maintain the precision and find the perfect edges for the plastic parts.Water jets help to ensure that the final cutting of the plastic sheet is perfect.You can make the product perfectly using a water knife cutting plastic.