Why Invest in an Automatic Embossing Laminating Machine? Exploring the Business Benefits

2024-08-22

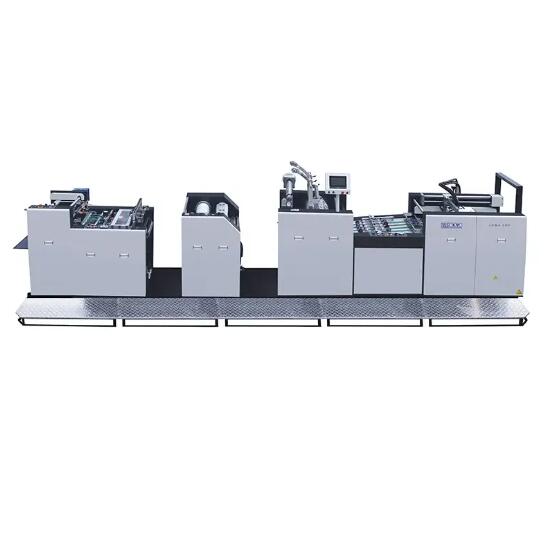

In today’s competitive marketplace, businesses in the printing, packaging, and publishing industries are constantly seeking ways to improve efficiency, reduce costs, and enhance product quality. One piece of equipment that has proven invaluable in achieving these goals is the Automatic Embossing Laminating Machine. In this blog, we’ll explore why investing in this machine can be a game-changer for your business, highlighting the key benefits and return on investment (ROI) you can expect.

1. Streamlined Production Process

One of the most compelling reasons to invest in an Automatic Embossing Laminating Machine is the ability to streamline your production process. Traditionally, embossing and laminating were separate processes, each requiring its own set of equipment and labor. By combining these into a single machine, you can:

- Reduce Setup Time: With one machine handling both tasks, there’s no need to switch between different pieces of equipment, saving valuable time.

- Minimize Labor Costs: Fewer machines mean fewer operators, which directly reduces labor costs. The automation capabilities also allow a single operator to manage the entire process, further enhancing efficiency.

- Increase Production Speed: The integration of embossing and laminating processes in one continuous workflow significantly increases production speed, allowing you to meet tight deadlines and large orders with ease.

2. Consistent High-Quality Output

Quality is a critical factor in maintaining customer satisfaction and brand reputation. The Automatic Embossing Laminating Machine is designed to deliver consistent, high-quality output with every run. Key features that ensure quality include:

- Precision Control: Advanced machines come with programmable settings that allow precise control over pressure, temperature, and speed, ensuring that each product meets exact specifications.

- Uniform Results: Automation minimizes the risk of human error, producing uniform results across large batches. This consistency is crucial for maintaining a professional standard in your products.

- Defect Reduction: By automating the process, the machine reduces the likelihood of defects such as misalignment, uneven embossing, or imperfect lamination, which can occur with manual operations.

3. Versatility in Applications

The Automatic Embossing Laminating Machine is highly versatile, making it a valuable asset for businesses serving multiple markets. Whether you’re producing packaging, promotional materials, or decorative items, this machine can handle a wide range of materials and designs. Its versatility includes:

- Material Compatibility: The machine can work with various substrates, including paper, cardboard, plastic, and certain fabrics. This flexibility allows you to diversify your product offerings and cater to different industries.

- Design Flexibility: Whether you need simple logos or complex patterns, the machine can emboss and laminate a variety of designs, giving you the creative freedom to meet client needs.

4. Enhanced Product Durability

Lamination not only enhances the visual appeal of a product but also significantly improves its durability. By investing in an Automatic Embossing Laminating Machine, you ensure that your products are more resistant to wear and tear, moisture, and environmental factors. This durability translates into:

- Longer Product Lifespan: Laminated products are less likely to degrade over time, making them more appealing to consumers who value longevity.

- Better Customer Satisfaction: Durable products lead to fewer returns and complaints, enhancing customer satisfaction and loyalty.

- Competitive Advantage: Offering high-quality, durable products can set you apart from competitors, particularly in industries like packaging and publishing, where durability is a key selling point.

5. Cost-Effectiveness and ROI

While the initial investment in an Automatic Embossing Laminating Machine may be significant, the long-term cost savings and ROI make it a wise business decision. The machine’s ability to reduce labor costs, increase production speed, and minimize defects directly impacts your bottom line. Consider the following:

- Lower Operational Costs: Automation reduces the need for multiple machines and operators, leading to lower operational costs over time.

- Increased Production Capacity: The machine’s efficiency allows you to take on more projects and larger orders, increasing your revenue potential.

- Improved Profit Margins: By reducing waste and enhancing product quality, you can improve your profit margins, as higher-quality products often command higher prices.

Conclusion

Investing in an Automatic Embossing Laminating Machine is not just about upgrading your equipment; it’s about transforming your business operations. From streamlining production and reducing costs to enhancing product quality and durability, this machine offers numerous benefits that can lead to significant returns on investment. As the demand for high-quality, durable printed materials continues to grow, having the right equipment in place is essential for staying competitive in the market. By understanding the advantages of this machine, you can make an informed decision that aligns with your business goals and drives future success.