Why Choose an FRP Grating Cover? Discover the Smarter, Safer Alternative to Traditional Covers

2025-05-12

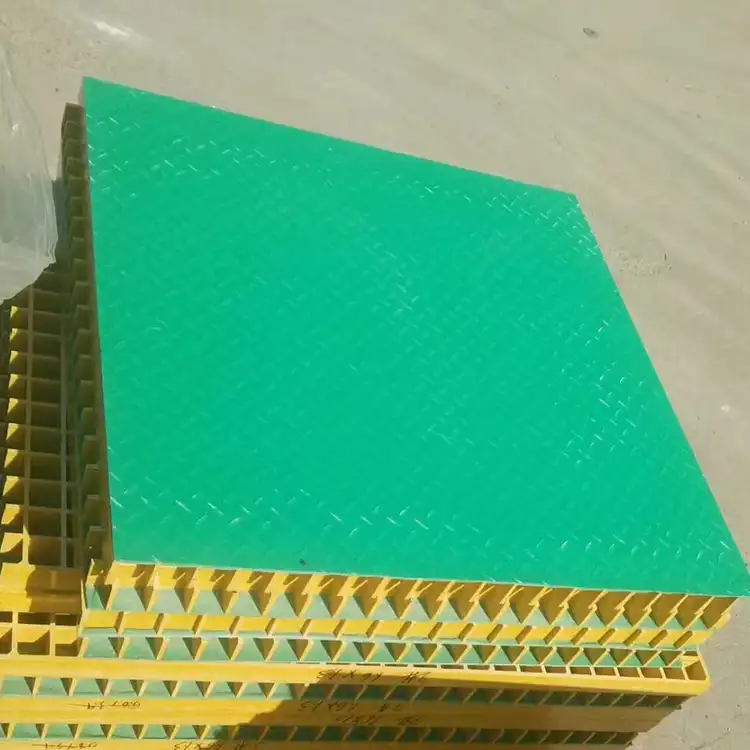

When it comes to industrial flooring, trench covers, or walkways, safety and durability are non-negotiable. Traditional metal grates may do the job, but they often fall short in corrosive environments or places that require lightweight, easy-to-install materials. That’s where the FRP Grating Cover steps in—a modern solution that balances strength, safety, and long-term performance.

What Makes FRP Grating Covers Stand Out?

1. Corrosion Resistance You Can Count On

One of the most significant advantages of FRP (Fiber Reinforced Plastic) grating covers is their outstanding resistance to corrosion. Unlike steel or aluminum, FRP doesn't rust or degrade when exposed to moisture, chemicals, or harsh weather. This makes it an ideal choice for chemical plants, wastewater facilities, marine environments, or any area prone to chemical spills or corrosive liquids.

2. Built for Long-Term Durability

Made from a composite of fiberglass and resin, FRP grating covers are engineered for high durability. They resist cracking, warping, and surface wear—even under heavy loads or frequent foot traffic. This long-lasting performance means fewer replacements, lower maintenance costs, and greater peace of mind for facility managers.

3. Lightweight Yet Exceptionally Strong

Don’t let the weight fool you—FRP grating covers are light, but they’re built to perform. Their high strength-to-weight ratio makes them far easier to transport and install than traditional metal covers, especially in elevated or hard-to-reach areas. Workers can often move and place them without heavy lifting equipment, cutting down on labor and time.

4. Anti-Slip for Enhanced Workplace Safety

Safety is always a top priority, especially in industrial or outdoor settings where floors can become wet or oily. FRP grating covers feature a textured, slip-resistant surface that provides secure footing, helping to reduce workplace accidents and keep your teams safe—rain or shine.

Where Can You Use FRP Grating Covers?

FRP grating covers are incredibly versatile. Common applications include:

1. Trench and drain covers in chemical plants or wastewater treatment facilities

2. Walkways and platforms in marine or offshore environments

3. Flooring in food processing plants, where hygiene and safety are key

4. Access covers in oil and gas sites, power plants, and factories

5. Public infrastructure like subways, bridges, and sidewalks

Whether you're replacing old, corroded grates or planning a new facility, FRP grating covers offer a low-maintenance, high-performance solution that adapts to a wide range of environments.

If you’re looking for a grating solution that combines safety, durability, and environmental responsibility, FRP grating covers are well worth the investment. From easier installation to better corrosion resistance, they offer long-term benefits that traditional metal covers simply can’t match.