What Is a Hot Runner in Injection Molding?

2025-08-05

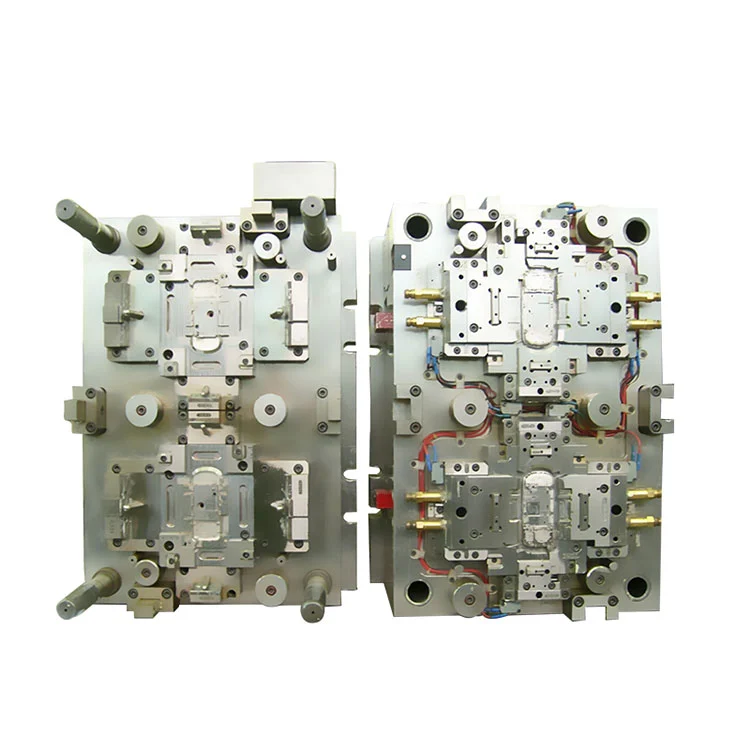

Hot runner systems have revolutionized plastic injection molding by improving efficiency and reducing waste. At Moldor, we specialize in manufacturing high-performance Hot Runner Mold systems that deliver precision and reliability.

Understanding Hot Runner Systems

A Hot Runner Mold is a heated component in injection molding that keeps plastic in a molten state as it travels from the machine nozzle to the mold cavities. Unlike cold runner systems that produce waste material, hot runners maintain continuous melt flow, offering significant advantages in production efficiency and material savings.

Key Features of Our Hot Runner Molds

Our factory produces hot runner mold systems with these exceptional characteristics:

Technical Specifications

|

Parameter |

Specification |

|---|---|

| Temperature Range | 50°C - 450°C |

| Heating Power | 100W - 1000W per zone |

| Nozzle Types | Open, valve gate, thermal tip |

| Material Compatibility | All thermoplastics |

| Control System | PID temperature control |

| Maximum Pressure | 250MPa |

Advantages of Moldor Hot Runner Systems

-

Material Savings: Eliminates runner waste

-

Faster Cycle Times: No need to cool/solidify runners

-

Improved Part Quality: Consistent melt temperature

-

Reduced Energy Consumption: Efficient heating design

-

Custom Solutions: Tailored to specific applications

What Is a Hot Runner in Injection Molding? - FAQs

FAQ 1: How does a hot runner system work?

A hot runner system maintains plastic in a molten state using precisely controlled heating elements. The molten plastic flows through heated manifolds and nozzles directly into the mold cavities, eliminating the need for secondary runner removal and reducing cycle times.

FAQ 2: What are the main components of a hot runner system?

Our hot runner mold systems consist of a manifold (distributes molten plastic), nozzles (deliver material to cavities), heating elements (maintain optimal temperature) and temperature controllers (ensure precise heat regulation).

FAQ 3: When should I choose a hot runner over a cold runner?

Hot runners are ideal for high-volume production, expensive materials where waste reduction matters, applications requiring fast cycle times, and complex parts with multiple gates.

Why Choose Moldor?

At Ningbo Moldor Plastic Co., Ltd., we combine precision engineering with rigorous quality control to deliver reliable hot runner solutions. Our systems are designed for maximum uptime, energy efficiency, and consistent performance. For more information about our hot runner mold technology or to discuss your specific requirements, contact us today.