Understanding the Function of the Fixed Lower Die in a Press Die Mold

2024-05-31

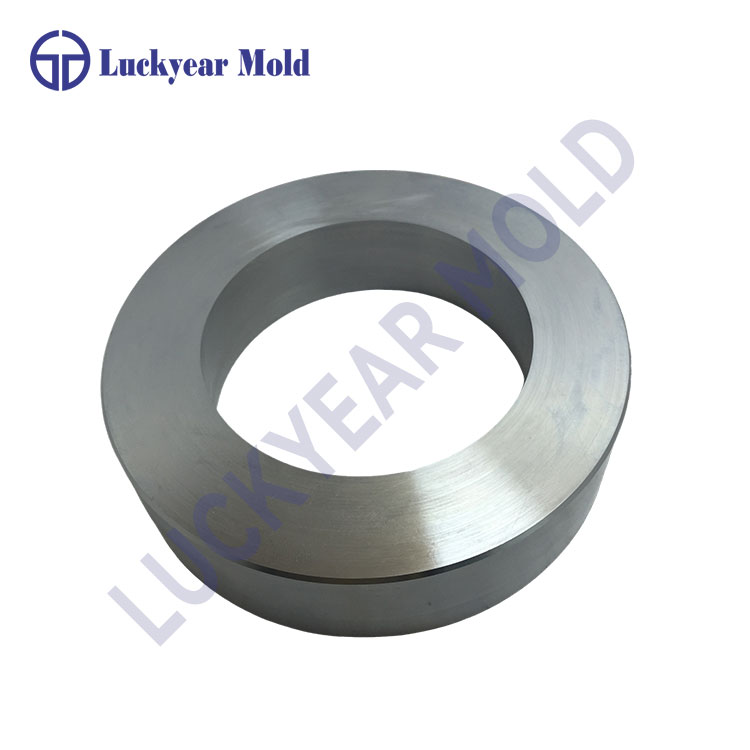

In the intricate world of metalworking and manufacturing, press die molds are precision tools that play a pivotal role in shaping and forming metal components. Among the various components of a press die mold, the fixed lower die, also known as the die block, holds a significant position. Let's delve deeper into the function of this crucial component.

The fixed lower die serves as the foundation and shaping element of the press die mold. It is the counterpart to the moving upper die, often referred to as the punch. Together, they work in harmony to create the desired metal product.

The primary function of the fixed lower die is to provide a cavity or shape that corresponds to the desired final product. As the punch descends, it forces the metal workpiece into this cavity, causing it to conform to the shape of the die. This process is known as metal forming or stamping.

The fixed lower die is made from a durable and wear-resistant material, such as tool steel. This ensures that it can withstand the repetitive forces and pressures exerted during the metal forming process. The material must also be able to maintain its shape and dimensions over time, ensuring consistent and accurate results.

In addition to its shaping function, the fixed lower die also serves as a support structure for the other components of the press die mold. It provides a stable base for the punch to operate against, ensuring that the metal workpiece is properly aligned and positioned during the forming process.

Furthermore, the design of the fixed lower die can impact the efficiency and productivity of the press die mold. A well-designed die can facilitate easy ejection of the formed product, minimize waste, and extend the mold's overall lifespan.

In conclusion, the fixed lower die plays a crucial role in the metal forming process. It provides the shaping cavity, serves as a support structure, and can impact the efficiency and productivity of the press die mold. Understanding its function and importance is essential for anyone involved in the metalworking and manufacturing industry.