How Parallel Comb Idlers Improve Conveyor System Reliability

2024-07-12

Introduction

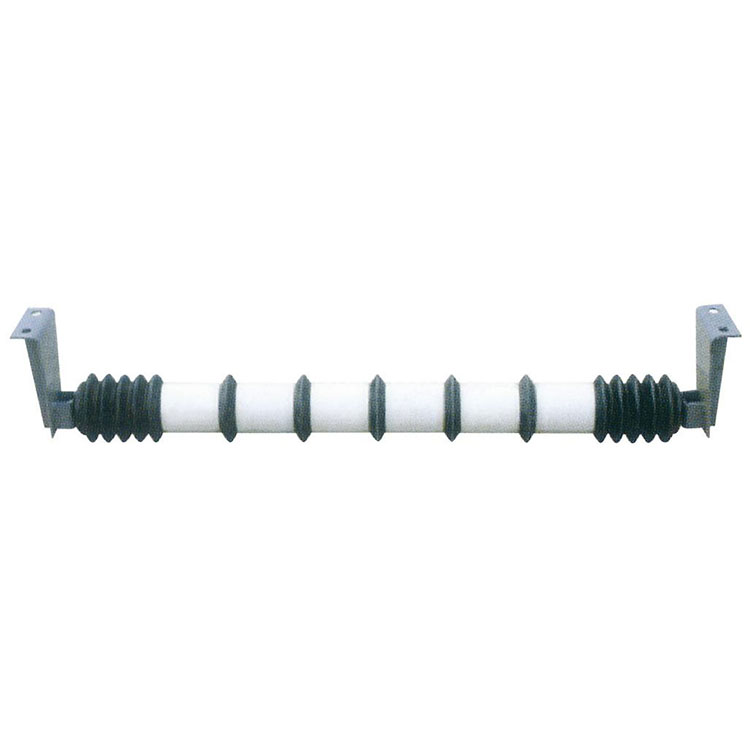

In any industry that relies on conveyor systems, reliability is key. The efficiency and productivity of operations depend heavily on the continuous, trouble-free function of these systems. A critical component that significantly contributes to this reliability is the Parallel Comb Idler. This blog will explore how Parallel Comb Idlers enhance the reliability of conveyor systems, their maintenance benefits, and best practices for integration.

Enhancing Conveyor System Reliability with Parallel Comb Idlers

1. Consistent Belt Support

- Parallel Comb Idlers provide uniform support across the entire width of the conveyor belt. This consistent support prevents sagging and reduces the risk of belt misalignment, which can cause operational disruptions.

2. Superior Load Distribution

- The comb design of these idlers ensures even load distribution, minimizing localized stress on the belt. This reduces wear and tear on both the belt and the idlers, enhancing the longevity of the entire system.

3. Effective Material Handling

- The comb structure helps contain materials on the belt, preventing spillage and maintaining a smooth flow. This is particularly beneficial in handling bulk materials, where spillage can lead to significant operational challenges.

4. Reduced Vibration and Noise

- Parallel Comb Idlers are designed to operate quietly and smoothly. The reduction in vibration and noise not only enhances the working environment but also decreases the wear on the conveyor system components, leading to longer service life.

Maintenance Benefits of Parallel Comb Idlers

1. Lower Maintenance Frequency

- The robust design and durable materials used in Parallel Comb Idlers result in lower maintenance requirements. This means fewer shutdowns for repairs and a more consistent operation.

2. Easy Replacement and Adjustment

- Modern Parallel Comb Idlers are designed for easy installation and replacement. Features such as quick-release mechanisms and tool-less adjustments make maintenance tasks simpler and faster.

3. Proactive Maintenance Opportunities

- With the integration of smart monitoring technologies, maintenance can be scheduled proactively. Sensors can provide real-time data on the condition of the idlers, allowing for maintenance to be performed before issues escalate into major problems.

4. Cost Savings

- Reduced maintenance frequency and the ability to address issues proactively lead to significant cost savings. There is less need for emergency repairs, and the overall lifecycle costs of the conveyor system are lowered.

Best Practices for Integrating Parallel Comb Idlers

1. Assess System Requirements

- Before integrating Parallel Comb Idlers, it's essential to assess the specific requirements of your conveyor system. Consider factors such as the type of materials being transported, belt speed, and load characteristics.

2. Choose the Right Idler Type

- Select Parallel Comb Idlers that are designed for your specific application. Factors such as the idler's material, size, and load capacity should match the needs of your conveyor system.

3. Proper Installation

- Ensure that the idlers are installed correctly to achieve optimal performance. Follow the manufacturer’s guidelines and seek professional assistance if necessary to avoid misalignment and operational issues.

4. Regular Inspections

- Conduct regular inspections of the Parallel Comb Idlers and the entire conveyor system. Look for signs of wear, misalignment, and other potential issues. Early detection and resolution of problems can prevent more significant disruptions.

5. Utilize Smart Monitoring

- If available, integrate smart monitoring technologies with your Parallel Comb Idlers. Real-time data on the performance and condition of the idlers can help in scheduling maintenance and avoiding unexpected downtime.

Conclusion

The reliability of conveyor systems is crucial for maintaining efficient and productive operations. Parallel Comb Idlers play a significant role in enhancing this reliability by providing consistent support, effective material handling, and reduced maintenance needs. By following best practices for integration and maintenance, businesses can ensure that their conveyor systems run smoothly and cost-effectively.