Exploring the Diverse Applications of Aluminum Sheet Stamping Across Industries

2024-04-17

Introduction:

Aluminum sheet stamping, a versatile manufacturing process, plays a crucial role in various industries due to its lightweight, durable, and corrosion-resistant properties. From automotive to aerospace, and from electronics to construction, the applications of aluminum sheet stamping are widespread and diverse. In this blog, we delve into the primary applications of aluminum sheet stamping across different sectors.

1. Automotive Industry:

Aluminum sheet stamping finds extensive use in the automotive sector, where lightweight materials are in high demand for enhancing fuel efficiency and improving performance. Components such as body panels, chassis parts, brackets, and heat shields are often manufactured using aluminum sheet stamping. Its ability to form complex shapes while maintaining structural integrity makes it an ideal choice for automotive manufacturers.

2. Aerospace Industry:

In the aerospace industry, where every ounce matters, aluminum sheet stamping plays a vital role in the production of aircraft components. From fuselage panels to interior fittings, many parts are fabricated using aluminum sheet stamping processes. The lightweight nature of aluminum reduces the overall weight of aircraft, contributing to fuel efficiency and enabling longer flight ranges.

3. Electronics and Consumer Goods:

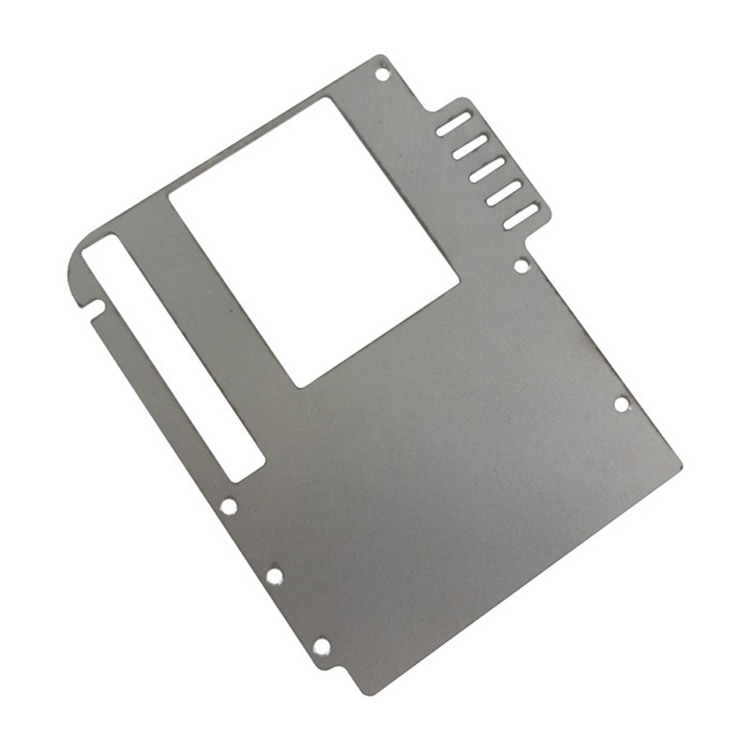

The electronics industry relies on aluminum sheet stamping for the production of casings, enclosures, and heat sinks for various devices such as laptops, smartphones, and appliances. Aluminum's excellent thermal conductivity makes it an ideal choice for heat dissipation, ensuring the longevity and performance of electronic components. Additionally, its aesthetic appeal and ability to be easily coated or anodized make it popular in consumer goods.

4. Construction and Architecture:

Aluminum sheet stamping plays a significant role in the construction industry, particularly in the fabrication of structural components, roofing materials, and facade systems. Its corrosion resistance makes it suitable for outdoor applications, while its lightweight nature simplifies transportation and installation processes. Moreover, aluminum's malleability allows for the creation of intricate architectural designs, making it a favorite among architects and designers.

5. Renewable Energy:

In the renewable energy sector, aluminum sheet stamping is utilized in the manufacturing of components for solar panels, wind turbines, and energy storage systems. Aluminum's lightweight properties make it ideal for mounting structures and frames, reducing the overall weight of renewable energy installations and simplifying installation processes. Additionally, its corrosion resistance ensures durability in outdoor environments, extending the lifespan of renewable energy infrastructure.

Conclusion:

The applications of aluminum sheet stamping across various industries highlight its versatility, durability, and cost-effectiveness. From automotive and aerospace to electronics, construction, and renewable energy, aluminum plays a crucial role in driving innovation and efficiency in modern manufacturing. As industries continue to evolve, the demand for lightweight, sustainable materials like aluminum is expected to grow, further cementing its position as a cornerstone of industrial production.