Building a Sustainable Future: The Environmental and Economic Advantages of the Fully Automatic Non Burning Brick Machine

2024-05-07

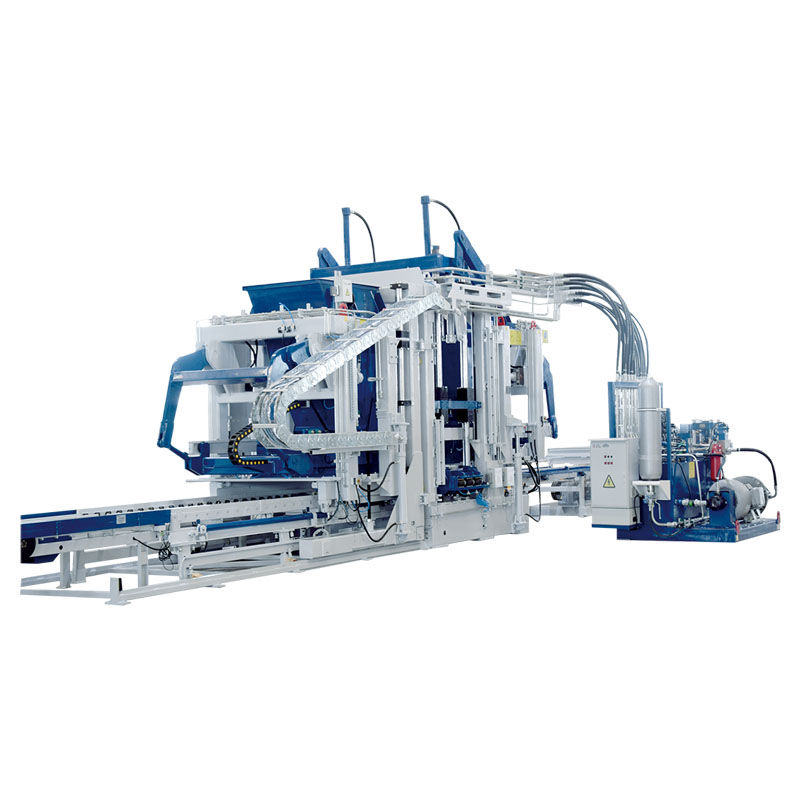

In the realm of construction, the quest for sustainability and cost-effectiveness has led to the development of innovative technologies that challenge traditional methods. Among these advancements, the Fully Automatic Non Burning Brick Machine stands out as a game-changer, offering a host of environmental and economic benefits compared to conventional brick-making methods. Let's explore how this revolutionary machine is reshaping the construction industry for the better.

1. Environmental Benefits:

a. Reduced Carbon Emissions: Conventional brick-making methods typically involve the burning of clay in kilns, a process that emits significant amounts of carbon dioxide and other pollutants into the atmosphere. In contrast, the Fully Automatic Non Burning Brick Machine eliminates the need for kiln firing, thereby reducing carbon emissions and mitigating the environmental impact of brick production.

b. Conservation of Natural Resources: By utilizing alternative materials such as fly ash, cement, and industrial waste, the Fully Automatic Non Burning Brick Machine helps conserve natural resources and reduce the depletion of clay reserves. This not only preserves valuable ecosystems but also minimizes the environmental footprint of brick production by reducing the need for clay extraction and transportation.

c. Waste Reduction: Traditional brick-making methods often result in high levels of material waste, with unused clay and byproducts from kiln firing ending up in landfills. The Fully Automatic Non Burning Brick Machine minimizes waste by optimizing material usage and recycling industrial byproducts, thereby reducing the burden on landfills and promoting a more circular approach to brick production.

2. Economic Benefits:

a. Cost Savings: The Fully Automatic Non Burning Brick Machine offers significant cost savings compared to conventional brick-making methods. By reducing energy consumption, material waste, and labor costs, this machine helps builders and developers optimize project budgets and maximize returns on investment. Additionally, the use of alternative materials can lower material procurement costs, further enhancing cost-effectiveness.

b. Increased Productivity: With its high production capacity and automated operation, the Fully Automatic Non Burning Brick Machine streamlines the brick-making process, enabling builders to meet project deadlines more efficiently. This increased productivity translates to faster construction timelines and reduced labor costs, resulting in greater overall profitability for construction projects.

c. Regulatory Compliance: As environmental regulations become increasingly stringent, businesses face growing pressure to adopt sustainable practices and reduce their carbon footprint. By utilizing the Fully Automatic Non Burning Brick Machine, builders and developers can demonstrate their commitment to environmental responsibility and ensure compliance with regulatory requirements, thereby avoiding potential fines and penalties.

In conclusion, the Fully Automatic Non Burning Brick Machine offers a compelling solution for builders and developers seeking to balance environmental sustainability with economic viability. By reducing carbon emissions, conserving natural resources, minimizing waste, and delivering cost savings and productivity gains, this innovative machine is driving positive change in the construction industry. As sustainability continues to take center stage in the built environment, the Fully Automatic Non Burning Brick Machine is poised to play a key role in shaping a more sustainable and prosperous future for generations to come.