Wholesale UL FM Gate Valves: A Guide to Product Selection and Compliance

2025-12-23

Selecting the right wholesale UL FM gate valves is critical for ensuring safety and compliance in fire protection systems. As industries prioritize stringent regulations, making informed choices becomes essential. In this guide, we delve into key factors for product selection, from material quality to certification standards. We're excited to share insights that can streamline your decision-making process. At DRIFCO, we specialize in high-performance valves designed to meet rigorous demands. Stay tuned as we explore how to navigate compliance and optimize your systems effectively.

Understanding the Basics of UL FM Gate Valves for Wholesale Applications

Gate valves are a foundational component in fluid control systems, and when paired with UL FM certifications, they become essential for wholesale applications requiring reliability and compliance. UL (Underwriters Laboratories) and FM (Factory Mutual) approvals signify that these valves meet rigorous safety standards, making them suitable for high-risk environments like industrial plants or commercial buildings. For wholesalers, this means offering products that not only function effectively but also adhere to legal and insurance requirements, enhancing client trust and reducing liability. By starting with these basics, businesses can better understand why investing in certified gate valves is a smart move for long-term operational security.

Unlike standard valves, UL FM gate valves undergo extensive testing for fire resistance, pressure handling, and durability. This ensures they perform reliably under extreme conditions, such as in fire protection systems or heavy machinery. For wholesale buyers, this translates to fewer maintenance issues and longer product lifecycles, which can lower overall costs and boost customer satisfaction. Emphasizing these unique features helps differentiate these valves in a crowded market, as clients often seek solutions that go beyond basic functionality to offer peace of mind in critical applications.

In wholesale settings, selecting the right gate valve involves considering factors like material composition, size compatibility, and ease of installation. UL FM certified valves often come with detailed documentation and support, making them a practical choice for bulk purchases. By focusing on these practical aspects, wholesalers can position themselves as knowledgeable partners, helping clients navigate complex specifications and choose valves that align with their specific needs. Ultimately, mastering the basics of these valves not only improves inventory decisions but also strengthens business relationships through informed recommendations.

Key Factors in Selecting the Right UL FM Gate Valve for Your Project

When choosing the perfect UL FM gate valve, it's vital to consider the specific demands of your project. Factors like the valve's material composition, pressure ratings, and compatibility with the fluid or gas in your system can make or break performance. Don't just go for a standard option; think about custom needs like corrosion resistance or temperature extremes that might call for specialized alloys or coatings. Authentic UL FM certifications ensure safety and reliability, so always verify compliance to avoid costly mistakes or safety issues down the line.

Beyond specifications, look at installation and maintenance aspects. Ease of access, durability under frequent use, and long-term serviceability are key to minimizing downtime and operational costs. Compare different brands or models for features like stem design or sealing mechanisms that enhance longevity. In industrial settings, a valve that integrates smoothly with existing infrastructure or offers smart monitoring capabilities can provide a competitive edge, making proactive choice crucial for project success.

Finally, weigh cost against value. While budget constraints are real, opting for a cheaper, non-compliant valve might lead to failures or non-compliance penalties. Assess total lifecycle costs, including energy efficiency and replacement schedules. Engage with suppliers to source valves that balance quality with affordability, ensuring your project stays on track without compromising on safety or performance standards. Each decision should align with your project's unique goals, fostering efficiency and reliability throughout its lifespan.

Ensuring Compliance with UL FM Standards in Valve Installation and Use

When installing valves, adhering to UL FM standards isn't just a regulatory checkbox—it's a crucial step for ensuring system safety and reliability. These standards, developed by Underwriters Laboratories (UL) and Factory Mutual (FM), set rigorous benchmarks for fire protection and property loss prevention. For example, during installation, components must be positioned correctly according to guidelines that specify clearances and mounting methods, helping prevent malfunctions in high-risk environments like industrial facilities or commercial buildings. Ignoring these specs could lead to leaks, pressure failures, or even catastrophic incidents, making compliance a non-negotiable aspect of any project.

Beyond the initial setup, regular use and maintenance play a key role in sustaining compliance. Engineers and technicians should conduct routine inspections to verify that valves operate within UL FM parameters, such as flow rates and response times. This involves checking for wear, corrosion, or damage that might compromise performance, especially in fire suppression or hazardous material systems. By integrating these checks into standard operating procedures, teams can proactively address issues before they escalate, ensuring long-term operational integrity and minimizing downtime or safety risks.

To truly stand out in the industry, go beyond mere adherence by embracing a culture of continuous improvement. Consider incorporating advanced monitoring tools, like IoT sensors or data analytics, to track valve performance in real-time against UL FM benchmarks. This data-driven approach not only enhances compliance but also optimizes efficiency, providing insights that can inform future designs or retrofit projects. Ultimately, by weaving these standards into every stage—from installation to ongoing use—you not only meet regulatory demands but also build a reputation for excellence and innovation in safety-critical applications.

Comparing Different Types of UL FM Gate Valves: Features and Benefits

Comparing Different Types of UL FM Gate Valves: Features and BenefitsComparing Different Types of UL FM Gate Valves: Features and Benefits

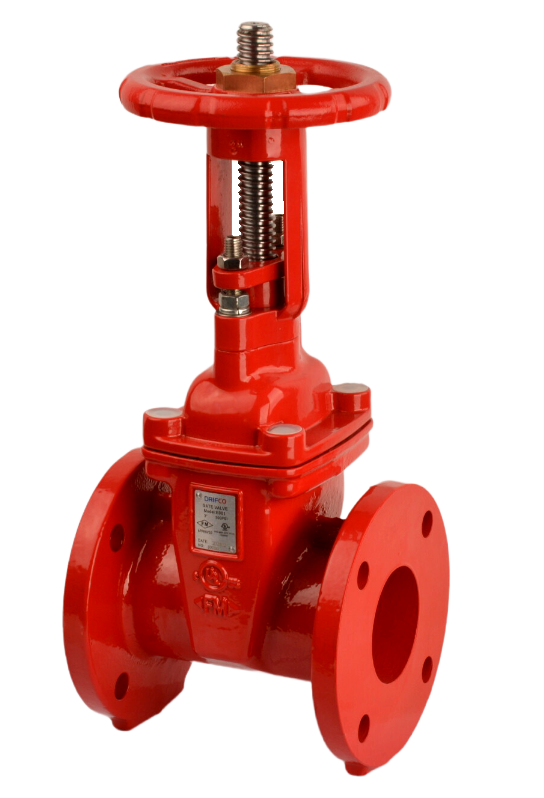

When exploring UL FM gate valves, it's crucial to consider the distinct types available, such as rising stem and non-rising stem models. Each type offers unique features that cater to specific applications. For instance, rising stem valves provide clear visual indication of valve position and are often preferred for maintenance-heavy environments due to their accessibility. Non-rising stem valves, on the other hand, save space and are ideal for installations with height restrictions. In terms of benefits, these valves ensure reliable fire safety compliance, with FM approval guaranteeing performance under demanding conditions.

Another key comparison point lies in material choices for UL FM gate valves, such as cast iron, bronze, and stainless steel variants. Cast iron valves are cost-effective and durable for standard applications, while bronze offers excellent corrosion resistance in harsh industrial settings. Stainless steel models excel in environments requiring superior hygiene or exposure to aggressive chemicals. The benefits extend beyond material durability—each type enhances system longevity and reduces maintenance costs over time. For example, stainless steel valves can withstand high-pressure scenarios without compromising flow control.

Evaluating locking mechanisms and operational features sets top-performing UL FM gate valves apart. Some models include tamper-proof locks to prevent unauthorized adjustments, ensuring system integrity in sensitive facilities. Others boast ergonomic handwheels or gear operators for easier handling. The benefits here are twofold: improved safety through controlled access and enhanced operational efficiency with minimal downtime. By comparing these details, users can select valves that not only meet regulatory standards but also optimize daily operations.

Best Practices for Sourcing and Distributing Wholesale UL FM Gate Valves

Securing wholesale UL FM gate valves begins with identifying reputable manufacturers known for stringent quality control and compliance. Look for suppliers with proven track records in producing valves that meet both UL (Underwriters Laboratories) and FM (Factory Mutual) standards, as these certifications ensure safety in fire protection systems. Conduct thorough due diligence by requesting samples for testing and verifying third-party audit reports to avoid potential issues down the line.

Establishing clear distribution channels is key to efficient supply chain management. Consider partnering with logistics providers specializing in industrial equipment to streamline delivery and reduce handling risks. Keep inventory levels optimized based on seasonal demand forecasts and regional building trends, ensuring you can meet client needs promptly without overstocking.

Building lasting relationships with both suppliers and end-users can set your business apart. Offer value-added services like installation support or custom packaging, and stay updated on evolving industry regulations to provide expert guidance. This proactive approach not only enhances reliability but also positions your wholesale operations as a trusted resource in a competitive market.

Addressing Common Challenges and Solutions in UL FM Gate Valve Systems

Gate valve systems in UL FM applications often face challenges like corrosion, sealing failures, and operational wear, especially in harsh environments. Solutions include using corrosion-resistant materials like stainless steel or coatings, along with regular maintenance to prevent leaks and ensure reliability. Proper installation and alignment can also mitigate stress on components, extending valve life and performance.

Another common issue is clogs or blockages from debris in fluid lines, which can hinder valve operation and compromise safety. To address this, implementing filtration systems and periodic cleaning schedules helps maintain flow integrity. Additionally, training personnel on proper handling and emergency procedures enhances system resilience, reducing downtime and risks.

Ensuring compliance with UL and FM standards is crucial for gate valve systems, as non-conformance can lead to safety hazards and regulatory penalties. Solutions involve conducting regular audits and testing, such as pressure and leakage checks, to verify adherence. Collaborating with certified experts and staying updated on standards revisions further optimizes system design and operation.

FAQ

Wholesale UL FM gate valves are specifically designed to meet stringent safety standards for fire protection systems, featuring rigorous testing for both fire and water flow, unlike standard valves which may only focus on basic pressure handling.

Always check for the official UL and FM marks stamped on the valve body and consult the manufacturer's documentation or online databases to confirm listing details, ensuring it's not just a claim without proper testing.

Assess the system's flow requirements and environmental conditions—for example, brass or ductile iron for corrosion resistance in damp areas, and ensure the size matches pipe specifications to maintain optimal pressure.

Yes, they're suitable for both, but for outdoor use, consider weather-resistant coatings or enclosures to protect against elements like UV exposure and freezing temperatures, per installation guidelines.

One frequent error is prioritizing low cost over certification validity, leading to non-compliant valves; avoid this by sourcing from reputable suppliers and requesting proof of testing reports upfront.

They often require more regular inspections, such as annual flow tests and checks for seal integrity, to ensure continued compliance with fire safety standards, whereas non-certified valves might have less rigorous upkeep.

Yes, recent revisions emphasize enhanced seismic performance and improved materials for higher temperature resistance, so it's wise to review current codes and choose valves that meet the latest 2023 editions.

Conclusion

Wholesale UL FM gate valves are fundamental components in fire protection systems, where selection and compliance determine system reliability and safety. Understanding their basics involves recognizing how these valves regulate flow in pipelines while meeting rigorous Underwriters Laboratories (UL) and Factory Mutual (FM) standards for fire safety. Key selection factors include valve size, pressure ratings, material compatibility (such as bronze or cast iron), and application-specific requirements like residential, commercial, or industrial settings. Ensuring compliance extends beyond product features to proper installation, regular testing, and adherence to local codes, which minimizes risks of failure during emergencies. By addressing these aspects, wholesalers can provide valves that not only perform optimally but also meet stringent regulatory demands, enhancing overall system integrity.

To stand out in the competitive wholesale market, it's crucial to compare different types of UL FM gate valves, such as rising stem vs. non-rising stem designs, each offering unique benefits like ease of maintenance or space efficiency. Best practices for sourcing involve partnering with reputable manufacturers, verifying certifications, and implementing quality control checks during distribution. Common challenges, such as corrosion or misalignment, can be mitigated through proactive solutions like using corrosion-resistant materials and providing comprehensive installation support. By integrating these insights from product selection to compliance and beyond, wholesalers can deliver superior valve systems that address real-world needs, foster client trust, and differentiate their offerings through tailored, reliable solutions that go beyond basic specifications.

Contact Us

Contact Person: George

Email: [email protected]

Tel/WhatsApp: 13863633883

Website: https://www.es-fire.com