Unlocking Efficiency with ODM Power Distribution Boxes: A Comprehensive Guide

2026-01-09

In today's fast-paced business landscape, efficiency isn't just a goal—it's a necessity. Yet, achieving seamless power distribution in industrial and commercial settings can be a persistent challenge, often mired in complex solutions and unclear outcomes. Enter the power of ODM power distribution boxes, a game-changing innovation that simplifies energy management while driving operational excellence. At Lugao, we've harnessed this potential to deliver tailored, reliable solutions that empower businesses to streamline their infrastructure and reduce downtime. This comprehensive guide explores how ODM power distribution boxes can unlock unprecedented efficiency, offering insights into their design, benefits, and real-world applications. Whether you're an engineer, facility manager, or decision-maker, discover how integrating smart power solutions can transform your operations and fuel future growth.

What Are ODM Power Distribution Boxes and Why They Matter

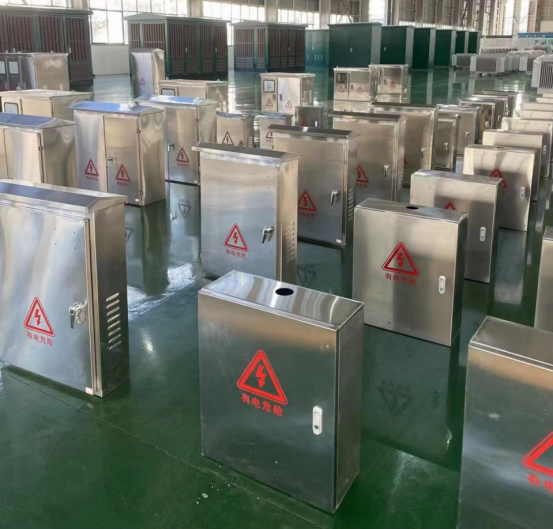

When exploring electrical infrastructure, ODM power distribution boxes stand out as custom-designed units crafted by Original Design Manufacturers. These aren't off-the-shelf products; instead, they're tailored solutions built from the ground up to meet precise customer requirements, ensuring seamless integration into specific systems or environments. By collaborating with an ODM, companies can specify everything from materials and dimensions to safety features and connectivity, resulting in a box that fits their exact operational needs, whether for industrial machinery, data centers, or renewable energy setups.

The significance of these boxes goes beyond mere customization. In today's fast-paced technological landscape, relying on generic distribution units can lead to inefficiencies, higher maintenance costs, or even safety hazards. ODM boxes address this by incorporating advanced components like smart meters, surge protectors, and modular designs that allow for easy upgrades. This adaptability not only enhances reliability but also future-proofs installations, helping businesses avoid costly overhauls down the line and maintain uninterrupted power flow in critical applications.

Moreover, opting for ODM power distribution boxes can be a strategic move for companies aiming to differentiate their products or operations. By embedding unique branding elements or proprietary technologies, these boxes offer a competitive edge in markets where performance and specificity matter. They foster innovation by enabling engineers to experiment with new layouts or materials, ultimately driving improvements in energy management and sustainability. In essence, they're not just boxes; they're pivotal tools that empower businesses to optimize power distribution with precision and foresight.

Key Features That Boost Operational Efficiency

When you implement the right tools, they can transform how your team works. Key features like automated workflows streamline repetitive tasks, freeing up time for strategic thinking. It's not just about saving hours; it's about reducing errors and boosting morale, as employees focus on high-value activities instead of mundane chores.

Real-time analytics provide a crystal-clear view of operations, allowing quick adjustments on the fly. This feature helps identify bottlenecks before they become major problems, enabling proactive decision-making. By leveraging data insights, organizations can optimize resource allocation and enhance overall performance.

Integration capabilities ensure that different systems work together seamlessly, eliminating data silos. This connectivity fosters collaboration across departments, speeding up processes and improving accuracy. Ultimately, these features create a more agile and responsive workplace, driving efficiency without sacrificing quality.

Customization Options Tailored to Your Specific Needs

We believe one size never fits all, which is why our customization solutions are designed to adapt seamlessly to your unique challenges. Instead of offering generic packages, we start by understanding your specific goals and constraints, crafting options that evolve alongside your business. Whether you need a slight tweak or a complete overhaul, our process ensures that every feature aligns perfectly with your vision, without any unnecessary fluff.

Our approach goes beyond simple adjustments—we collaborate directly with your team to uncover hidden opportunities for enhancement. By integrating your feedback at every stage, we create tailored options that not only meet but exceed expectations, making your experience feel genuinely bespoke. This hands-on method ensures that the final product reflects your distinct identity, rather than a cookie-cutter solution.

With flexibility at our core, we offer scalable customization that grows with you, avoiding the pitfalls of rigid systems. From initial setup to ongoing support, every aspect is fine-tuned to fit your needs, ensuring long-term efficiency and satisfaction. It's about crafting a solution that feels like it was made just for you, because it truly was.

Installation and Maintenance Best Practices for Longevity

To ensure your equipment lasts for years, proper installation is just as crucial as regular upkeep. Start by carefully reading the manufacturer's guidelines before assembly, as skipping steps or using incompatible tools can lead to premature wear. For instance, secure mounting on a stable surface prevents vibrations that might loosen components over time. Pay attention to environmental factors, too—placing devices in well-ventilated areas away from excessive heat or moisture can stave off corrosion and overheating, which are common culprits of early failure.

Routine maintenance is the backbone of longevity, but it's often overlooked until problems arise. Set a schedule for periodic checks, such as cleaning filters or lubricating moving parts monthly, based on usage intensity. Don't just wait for obvious signs of trouble; proactive inspections can catch minor issues like frayed cables or loose connections before they escalate into costly repairs. Keep a log of maintenance activities—it helps track performance trends and ensures tasks aren't forgotten, making upkeep more systematic and effective.

Beyond basic steps, adapt your practices to the specific needs of your equipment. For complex systems, consider professional servicing annually to calibrate sensors or update firmware, which optimizes efficiency. Train users on correct operation to avoid mishandling, and stock essential spare parts to minimize downtime during unexpected breakdowns. By integrating these tailored strategies into your routine, you'll not only extend lifespan but also enhance reliability, saving both time and resources in the long run.

Real-World Applications Across Diverse Industries

Industries from healthcare to finance are leveraging advanced technologies to solve real-world challenges. For example, in healthcare, AI-powered diagnostic tools assist doctors in detecting diseases earlier, improving patient outcomes and reducing costs. In retail, personalized recommendation engines enhance customer experiences by analyzing browsing habits and purchase history. These applications demonstrate how tailored solutions can drive efficiency and innovation across sectors, adapting to specific needs rather than relying on one-size-fits-all approaches.

In the manufacturing sector, the integration of IoT sensors and robotics streamlines production processes, minimizing errors and boosting productivity. For instance, predictive maintenance systems use data analytics to foresee equipment failures before they occur, preventing downtime and saving resources. Similarly, in agriculture, smart farming techniques like drone monitoring and soil analysis help farmers optimize crop yields and manage resources sustainably. These diverse uses highlight the flexibility of modern technologies in tackling industry-specific problems with precision.

Beyond traditional fields, emerging areas like renewable energy benefit from these applications by using smart grids to balance supply and demand efficiently. In logistics, real-time tracking and route optimization software reduce delivery times and environmental impact. Such cross-industry adoption underscores a broader trend where interconnected systems foster resilience and growth, empowering businesses to navigate complex environments while delivering tangible value to users.

How to Choose the Right ODM Box for Your Project

Selecting an ODM (Original Design Manufacturer) box for your project can feel overwhelming with so many options available. Start by clearly defining your project's requirements, such as size, material, and production volume. Many manufacturers offer custom solutions, so don't hesitate to share your specific needs to find a box that fits perfectly, rather than settling for a standard design. This proactive approach can save time and ensure your product stands out on the shelf.

Consider the manufacturer's expertise and experience in your industry. Look for ODM partners who have a track record with similar projects, as they'll be better equipped to handle challenges like material sourcing or complex designs. It's also wise to request samples to evaluate quality firsthand, checking details like durability and finishing. A reliable partner will work closely with you to refine the design, ensuring it aligns with your brand's aesthetic and functional goals.

Don't overlook logistics and cost factors. Discuss lead times, shipping options, and minimum order quantities upfront to avoid surprises later. Balancing quality with budget is key; sometimes, a slightly higher investment in a durable, well-designed box can enhance your product's perceived value. By focusing on these aspects, you'll choose an ODM box that not only protects your product but also elevates your overall project success.

FAQ

ODM (Original Design Manufacturer) power distribution boxes are custom-designed electrical enclosures that streamline power distribution in industrial or commercial settings. By tailoring designs to specific needs, they reduce energy waste, simplify maintenance, and optimize space use, boosting overall operational efficiency.

Unlike standard solutions that offer a one-size-fits-all approach, ODM power distribution boxes are customized during the design phase to meet unique requirements. This ensures better integration with existing systems, higher safety standards, and improved scalability, resulting in fewer compromises and greater long-term value.

Yes, many ODM power distribution boxes are designed with compatibility for smart technologies. They can incorporate IoT sensors, remote monitoring capabilities, and automated controls, allowing for real-time data analysis, predictive maintenance, and reduced manual intervention, making them ideal for modern automated environments.

Industries such as manufacturing, data centers, telecommunications, and renewable energy sectors gain significant advantages. These boxes provide reliable power management in high-demand scenarios, support complex electrical loads, and adapt to harsh conditions, ensuring uninterrupted operations and safety compliance.

Initially, ODM boxes may have higher upfront costs due to customization. However, they often lead to cost savings over time by minimizing energy losses, reducing downtime through tailored reliability, and lowering maintenance expenses, offering a better return on investment compared to generic alternatives.

When choosing an ODM manufacturer, prioritize their expertise in electrical engineering, proven track record with similar projects, adherence to safety certifications, and ability to provide ongoing support. Quality materials, design flexibility, and post-installation service are crucial for optimal performance and durability.

ODM power distribution boxes promote sustainability by enabling precise energy distribution, which reduces overall consumption. Custom designs can incorporate energy-efficient components, support renewable energy integration, and minimize material waste, aligning with green initiatives and helping organizations meet environmental goals.

Conclusion

This comprehensive guide explores ODM power distribution boxes as essential tools for enhancing efficiency in electrical systems. ODM boxes are customizable units designed to manage power distribution with precision, offering tailored solutions that address specific operational needs. Their significance lies in providing reliable and adaptable frameworks for diverse industries, ensuring optimal performance and safety. By incorporating key features such as modular designs and advanced components, these boxes boost operational efficiency while minimizing downtime. The guide emphasizes how their customization options allow businesses to fine-tune systems for unique requirements, fostering flexibility and innovation in power management.

Practical aspects like installation and maintenance best practices are covered to ensure longevity and consistent performance, supported by real-world applications across sectors such as manufacturing, data centers, and renewable energy. To select the right ODM box, the guide advises evaluating project-specific factors, including load capacity, environmental conditions, and scalability. Ultimately, this resource highlights how ODM power distribution boxes unlock efficiency by integrating robust features, customization, and industry insights into a cohesive solution for modern electrical demands.

Contact Us

Contact Person: Doreen

Email: [email protected]

Tel/WhatsApp: 8618057712366

Website: https://www.liugaopower.com/